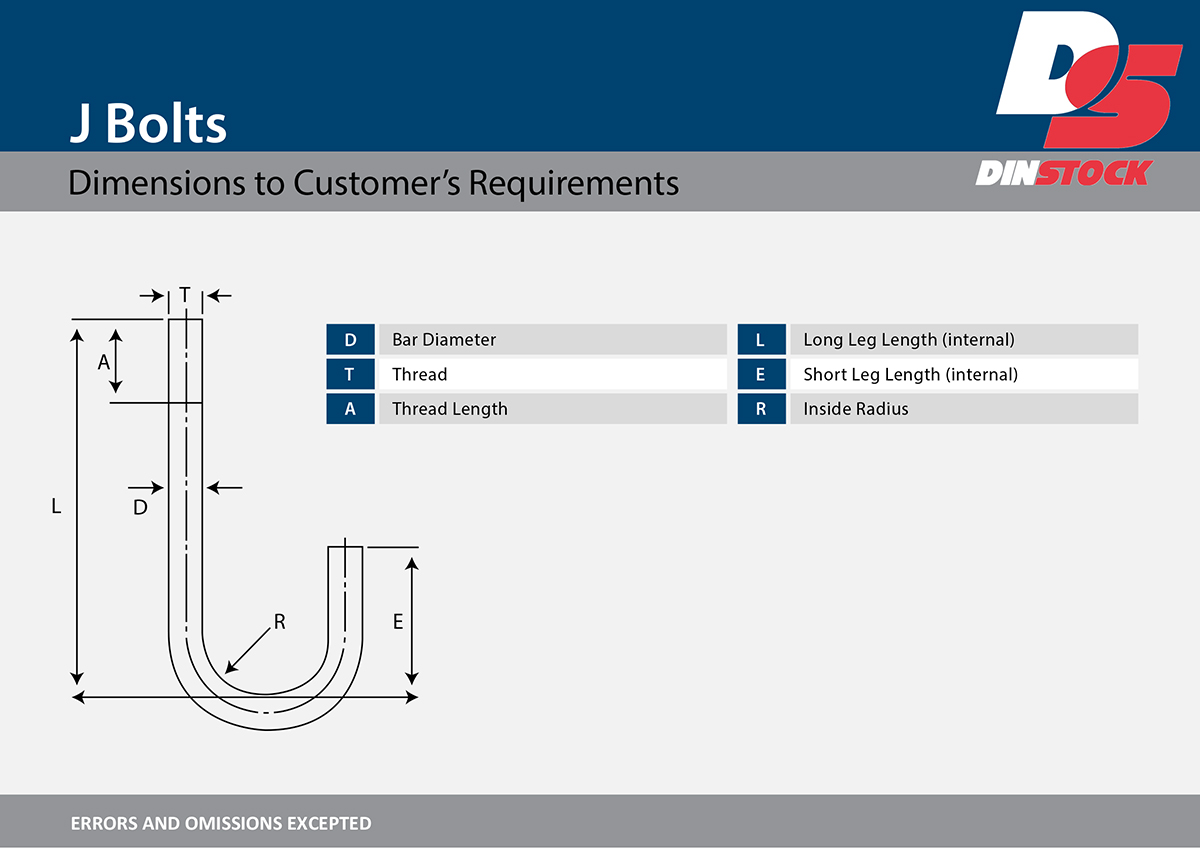

We can manufacture and supply J-Bolts to meet any requirement.

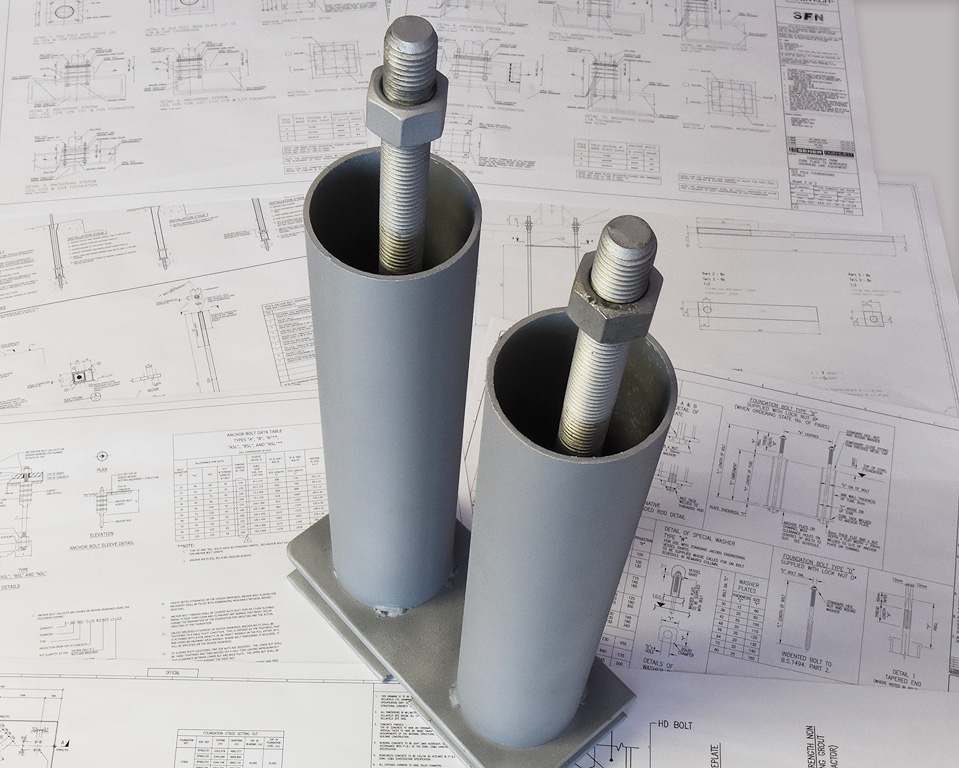

We can also manufacture and supply fabricated foundation assemblies which include J-Bolts.

Available in all material grades and coatings, including stainless steel.

Dinstock can also provide any ancillary products required such as nuts and washers and square/round anchor plates which can also be manufactured to your requirements.

See below table or forward your drawing to us for quotation.

J Bolts, also known as hook bolts or roofing bolts, are versatile fasteners extensively used across various industries. Their distinctive ‘J’ or hook shape makes them particularly effective for securing materials to steel or concrete structures. Here’s a closer look at J Bolts and their different applications:

Versatile Uses of J Bolts

- Roofing and Cladding: J bolts are frequently utilized in the roofing industry to fix cladding and roofing panels to steel frames. Their design allows the hook to fit over the edge of metal beams, effectively preventing the bolt from turning when tightened. This feature eliminates the need for access to the hook side during installation, making them ideal for challenging or restricted spaces. To ensure a weatherproof seal and enhanced durability, it is recommended to use spat or sela washers along with J bolts.

- Construction and Structural Support: In construction, J bolts are often employed to anchor structural supports and other components to concrete or masonry. Their hook shape ensures a secure grip, which is crucial for maintaining structural integrity. They are commonly used in foundation work, bridge construction, and securing posts or beams.

- Signage and Outdoor Fixtures: J bolts are also used for mounting signage and other outdoor fixtures. Their robust design ensures that signs remain securely attached even under adverse weather conditions.

Stainless Steel J Bolts

For applications requiring enhanced resistance to corrosion and extreme conditions, stainless steel J bolts are an excellent choice. Stainless steel provides superior durability and longevity, making these bolts ideal for environments exposed to moisture, chemicals, or high temperatures.

Benefits of Stainless Steel J Bolts:

- Corrosion Resistance: Stainless steel J bolts are highly resistant to rust and corrosion, ensuring long-lasting performance in harsh environments.

- Strength and Durability: Stainless steel offers superior tensile strength compared to other materials, making these bolts suitable for heavy-duty applications.

- Aesthetic Appeal: The sleek and polished finish of stainless steel J bolts adds a professional look to installations, which is beneficial for visible applications like signage and architectural features.

Applications of Stainless Steel J Bolts:

- Marine and Coastal Areas: Ideal for use in marine environments where exposure to saltwater can accelerate corrosion.

- Chemical Processing: Suitable for environments where exposure to chemicals is prevalent.

- Architectural and Aesthetic Projects: Used in projects where both functionality and appearance are important.

By selecting the appropriate J bolt for your application, whether standard or stainless steel, you can ensure a secure and reliable installation that meets your specific needs.