Dinstock manufactures a broad range of standard ‘Cold-Formed‘ and ‘Hot Forged’ fasteners in most materials, head styles, and grades from M10 to M100 diameter. We specialise in the production of large diameter and long length non-standard fasteners, from ‘Hot Forged’ bolt forgings M10 to M76 diameter and up to 1.5M in length, and all from stock. We have in-house manufacturing capability for roll and machine threading, CNC machining, as well as hardness, rotation, and tensile testing.

We manufacture the following products:

Our range of machinery for the production of standard and non-standard fasteners includes the following:

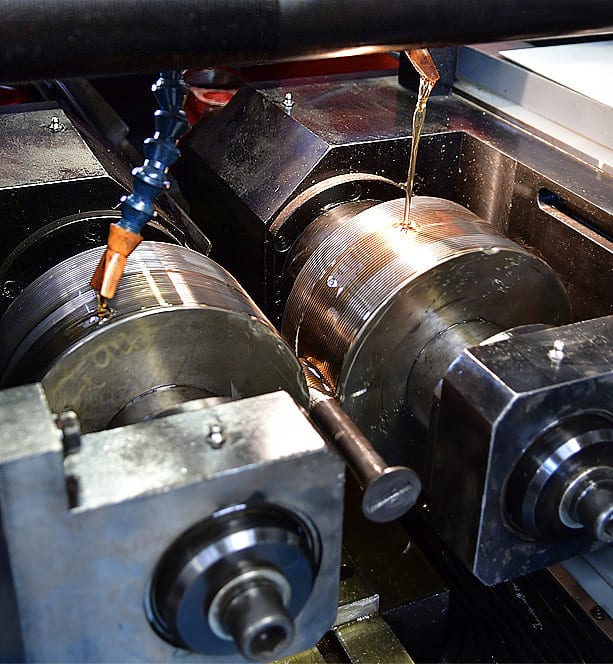

Thread Rolling – TRT50

This machine has the capability to thread up to M64 diameter.

Thread rolling is a process that has been around for over a hundred years. It is a cold-forming process that can be performed on any ductile metal and is the preferred method for producing strong, smooth, precise, and uniform external thread forms.

The basic mechanism involves hardened steel dies reshaping the material surface of a cylindrical blank under high pressure into a thread form. Other threading processes remove material to produce the thread form, whereas thread rolling reshapes the material.

The cylindrical workpiece (or blank) is fed into the machine and the dies squeeze the blank while rotating it to produce the threads.

Every thread form, shape, and size has a unique set of dies which are typically ground from heat-treated tool steel. The dies have the reverse form of the finished thread. Properly formed threads require that the dies are exactly lined up and track properly in order to avoid internal defects, such as overlaps, cracks, folds, seams, and craters.

Thread rolling produces a superior quality thread whilst retaining a higher degree of accuracy and greatly reduced production times when compared with other thread manufacturing methods.

Conventional Thread Cutting – Teledyne Landis Model: 32LM

Our conventional thread cutting machines have the capability to cut thread up to M100 diameter in grades ranging from mild steel through to high tensile steel grade 12.9.

Landis Thread Cutting tools are excellent for producing UN, BSF, Whitworth and Metric straight threads, NPT, NPTF, NPSM, BSTP, BSPP and API pipe threads.

XYZ CNC Machine – Model: VL425

Given our CNC capabilities, we are able to manufacture from M12 thru to M64. It also provides us with the ability to machine ‘specials’ to drawings for the grades described above.

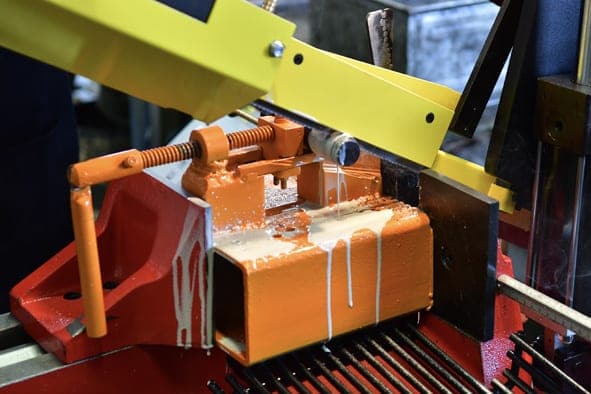

Bandsaw – Bianco Model: 330SAE

The Bianco metal cutting bandsaw is manufactured in Italy with reliability and accuracy its first consideration. All machines have modern cast bows in special alloys to ensure one of the highest precision Bandsaw ranges available.

Cutting capabilities – for bars, threaded bar, tubes and other steel work.

Hot Forged Fasteners are essential components for many applications due to their superior strength, durability and reliability. Our hot forged fasteners are made with advanced manufacturing techniques, ensuring that they meet the highest standards of performance. Hot Forged Fasteners are used in a variety of industries including construction, automotive, aerospace and manufacturing.

Benefits of Hot Forged Fasteners:

The hot forging process improves the grain structure so it is more consistent, which results in improved tensile and yield strength so the fastener is stronger and more resilient under stress.

Our manufacturing capabilities allow us to produce hot forged fasteners with high precision, offering uniformity which is crucial in applications that require fasteners to be made to a uniform specification. As well as this, we can create fasteners in various sizes, materials and grades which can suit uses in a wide range of industries.

At Dinstock we pride ourselves on our in-house manufacturing capabilities, including CNC machining and rigorous testing processes. All of our fasteners also undergo comprehensive quality checks so you can be sure when you order from us your components will meet industry standards and your specifications. If you would like to speak to us about hot forged fasteners, then our expert team is ready to assist you. Get in touch today!